Applications:

1. It can be directly installed in the slag blocking and bailing or sludge dewatering equipment, which can be made into a sealed structure for conveying and pressing. It can collect and improve the environment and reduce the amount of slag, which is convenient for subsequent treatment.

2. Shaftless are generally used for ordinary dense occasions; shafts are generally used for higher density occasions.

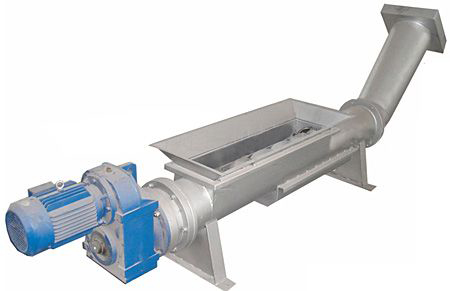

3. Ly type rotary extrusion screw press takes pressing as the main function, and has certain slag conveying and lifting function. It is suitable for occasions with short conveying distance and low lift, and generally has shaft structure; wly type gravity plate extrusion screw conveyor press mainly has conveying function, or has the function of integration of conveying and pressing, and generally has no shaft structure.

Equipment features:

1. Fully automatic electrical protection can realize the joint control with the grid cleaner.

2. The structure is compact and easy to install, and can be fixed by expansion bolt.

3. The groove is lined with wear-resistant material, convenient for maintenance and long service life.

4. It can operate in airtight condition with low noise and improve environment.

5. Length, angle and outlet hopper can be customized.

6. Spiral blade is made of stainless steel or manganese steel, with high strength and corrosion resistance.